Carf rebel pro

#451

My Feedback: (11)

I know some dont like my scheme, but Im not a fan of that caymen scheme in any color. It looks like a paint job a chinese knock off EDF would use. Further, its a scheme I could paint myself which says something.

But to each their own. Mine will need a new paint job by the 5th flight with the luck IM having.

But to each their own. Mine will need a new paint job by the 5th flight with the luck IM having.

Last edited by essyou35; 10-25-2022 at 04:02 PM.

#452

Senior Member

Back to our regular schedule postings.................

Congratulations to Chad Northeast and Jason Schulman on the TOC placing in Tuscon. Great flying.

Congratulations to Chad Northeast and Jason Schulman on the TOC placing in Tuscon. Great flying.

#453

Senior Member

Here's my setup with my Map holder ahead of the six liter tank, I also placed my electron gear pack beside the map for balancing.

#454

My Feedback: (11)

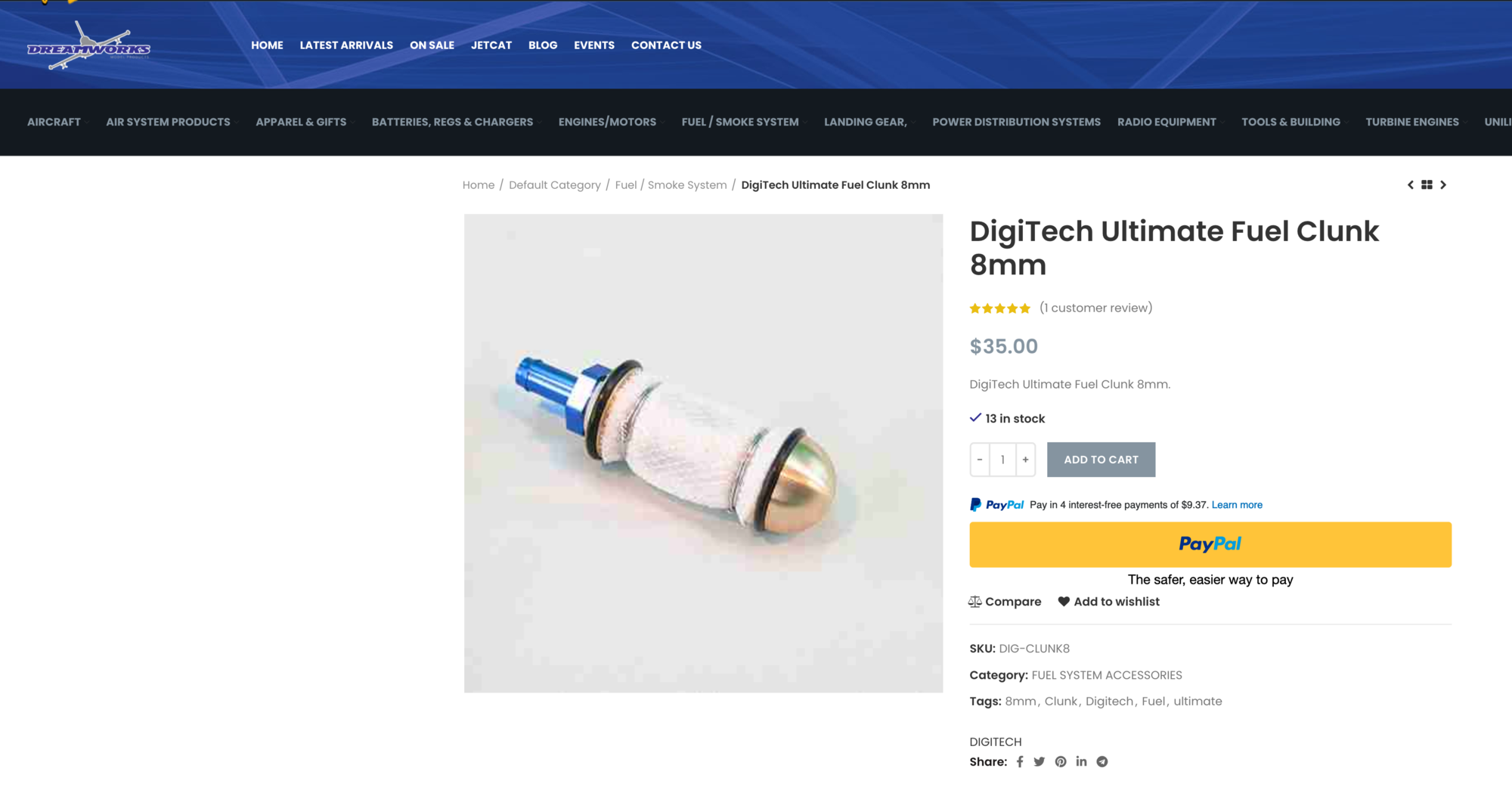

I ordered some of that Viton tubing from McMaster car, comes out to $10 a foot! I tried using BVM clunk like 6mm but it wont let clunk reach the front of the tank (the big digitech clunk) as the line binds on the side of the tank. Im wondering I should remove the orings off the clunk as well.

Its still going to suck significant air when the tank is 1/2 full and I rotate upside down or do a dive. Im hoping the new tubing will fix it. If not, I do not understand how no one else has this issue unless they dont fly upside down or do long dives.

Its still going to suck significant air when the tank is 1/2 full and I rotate upside down or do a dive. Im hoping the new tubing will fix it. If not, I do not understand how no one else has this issue unless they dont fly upside down or do long dives.

#455

My Feedback: (11)

Just to prove I know how to fly  This is my jetlegend viper (now BVM). This is a bit more calm of a flight than usual but you can get the point. I have a intairco UAT and 3 tanks and I land with only a 1/4" air bubble in the UAT.

This is my jetlegend viper (now BVM). This is a bit more calm of a flight than usual but you can get the point. I have a intairco UAT and 3 tanks and I land with only a 1/4" air bubble in the UAT.

I know everyone loves the rebel, but this viper is far superior. It wont fly as slow, but its way faster and has a wider envelope, plus I can land it at mock 2 and it will just stick to the runway!

This is my jetlegend viper (now BVM). This is a bit more calm of a flight than usual but you can get the point. I have a intairco UAT and 3 tanks and I land with only a 1/4" air bubble in the UAT.

This is my jetlegend viper (now BVM). This is a bit more calm of a flight than usual but you can get the point. I have a intairco UAT and 3 tanks and I land with only a 1/4" air bubble in the UAT.I know everyone loves the rebel, but this viper is far superior. It wont fly as slow, but its way faster and has a wider envelope, plus I can land it at mock 2 and it will just stick to the runway!

#456

Senior Member

So did you try the 8mm fuel clunk in your system, the 6mm fuel clunk

Here's the 6mm clunk which isn't big enough for the flow for large engine like our.

#459

Senior Member

I ordered some of that Viton tubing from McMaster car, it comes out to $10 a foot! I tried using BVM clunk like 6mm but it wont let clunk reach the front of the tank (the big digitech clunk) as the line binds on the side of the tank. Im wondering I should remove the orings off the clunk as well.

It's still going to suck significant air when the tank is 1/2 full and I rotate upside down or do a dive. I'm hoping the new tubing will fix it. If not, I do not understand how no one else has this issue unless they don't fly upside down or do long dives.

It's still going to suck significant air when the tank is 1/2 full and I rotate upside down or do a dive. I'm hoping the new tubing will fix it. If not, I do not understand how no one else has this issue unless they don't fly upside down or do long dives.

After half tank I limit my maneuvers in order not to get as much air into the MAP tank.

Also I cut the throttle to 1/4 when coming down from vertical descents and apply the throttle just before or near the bottom of the maneuver gradually.

It's Much easier on the airframe and it doesn't rush you into your next maneuver.

#460

Senior Member

Haven't seen too many mount the MAP vertical .

The following users liked this post:

Skunkwrks (11-01-2022)

#463

Senior Member

#464

My Feedback: (53)

Your stating thing that have factual truth…..doing down line At ¾ throttle…..that’s not F3S, .that speed demon, you won’t get constant speed because there’s no way you can climb at the same speed….basic pattern stuff..

#465

My Feedback: (53)

Skunkwerks Yeah, I keep telling Jonathan to take a vacation down here to Texas so he can fly the Max. I've flown all the Rebel models save the Hot now and they all fly very close to one another. I have no issues so far with the wing nuts but the fuse is massive on the Max. I'm a big boy and that airplane makes me look like a normal sized human. It's very easy to get my entire arm in the fuse to tighten or loosen the wing nuts.

Dansy Those Seacraft nuts.....do they fit on the existing aluminum studs or are the stock ones not 6mm? PS - I'm just trying to save myself from pulling out the calipers.

Dansy Those Seacraft nuts.....do they fit on the existing aluminum studs or are the stock ones not 6mm? PS - I'm just trying to save myself from pulling out the calipers.

#466

My Feedback: (11)

I didnt take a photo of my UAT after my flameout but I did take a photo of this air bubble. Is this too much air to be trapped in the fuel filter? I had it hnorizontal instead of vertical. Im 99% sure this did not come out of the UAT it ended up in there post UAT. So it sucked it from somewhere maybe the cut off valve or it was trapped in the filter and came out. thoughts?

#467

My Feedback: (53)

By looking at the list of jets you own…I would assume you know how to setup and prime the system pretty well, but in case…here my taught..

‘’With Festo and Pisco connection, the tubing has to be cut perfectly 90* or there’s a chance of air leaking…..I also try to go into them square without a bow like at your valve in the picture.

When I prime with these filters….I prime extra long….and wiggle the filter a lot until no bubble come out of it, after that it’s primed and never have to do it again…..the first time you put fuel in any UAT or filter it takes a little time to take all the air out…the position of the filter has nothing to do..I have installed them in different attitude…..but horizontal is harder to prime correctly.

But I doubt the air bubble showed actually come from the filter it’s very large, unless you didn’t prime the motor and just started without prime ?? It look more like an air leak in a line…??

‘’With Festo and Pisco connection, the tubing has to be cut perfectly 90* or there’s a chance of air leaking…..I also try to go into them square without a bow like at your valve in the picture.

When I prime with these filters….I prime extra long….and wiggle the filter a lot until no bubble come out of it, after that it’s primed and never have to do it again…..the first time you put fuel in any UAT or filter it takes a little time to take all the air out…the position of the filter has nothing to do..I have installed them in different attitude…..but horizontal is harder to prime correctly.

But I doubt the air bubble showed actually come from the filter it’s very large, unless you didn’t prime the motor and just started without prime ?? It look more like an air leak in a line…??

#468

My Feedback: (46)

By looking at the list of jets you own…I would assume you know how to setup and prime the system pretty well, but in case…here my taught..

‘’With Festo and Pisco connection, the tubing has to be cut perfectly 90* or there’s a chance of air leaking…..I also try to go into them square without a bow like at your valve

‘’With Festo and Pisco connection, the tubing has to be cut perfectly 90* or there’s a chance of air leaking…..I also try to go into them square without a bow like at your valve

#469

Senior Member

Note the fuel nipple on the engine is a swivel so you can turn and make the line straight. Square cuts on the tubing is very important fo sealing plus making sure the tube is into the fitting helps.

#470

Hello

I'm starting my Rebel Pro build now. I could use some help with the flap servo and arm installation. What is the servo arm length that is commonly being used and is the arm attached pointing up or down?

Some pictures of your installations would be appreciated.

Thanks for your help

I'm starting my Rebel Pro build now. I could use some help with the flap servo and arm installation. What is the servo arm length that is commonly being used and is the arm attached pointing up or down?

Some pictures of your installations would be appreciated.

Thanks for your help

#471

Senior Member

Here's my setup with the Carf 3mm rod attached to the 1" arm, which gets 55 degrees of travel.

#472

My Feedback: (1)

Hello

I'm starting my Rebel Pro build now. I could use some help with the flap servo and arm installation. What is the servo arm length that is commonly being used and is the arm attached pointing up or down?

Some pictures of your installations would be appreciated.

Thanks for your help

I'm starting my Rebel Pro build now. I could use some help with the flap servo and arm installation. What is the servo arm length that is commonly being used and is the arm attached pointing up or down?

Some pictures of your installations would be appreciated.

Thanks for your help

#473

Senior Member

It requires more mechanical force when the arm is at 90 degrees to the servo. The servo could stall from pushing so hard. Just saying